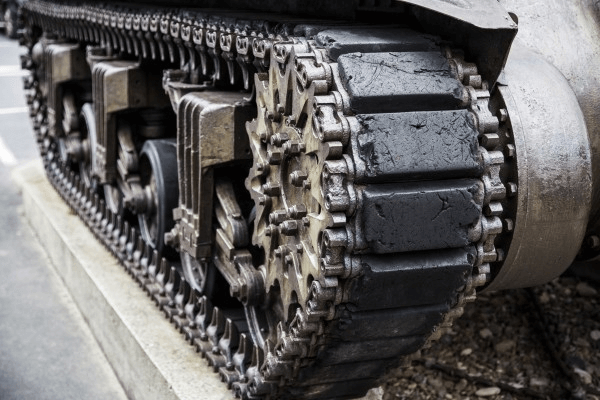

The vast majority of the prototyping we undertake at Nu-Cast, as well as many of the component parts that we make as a result of the concurrent engineering process and into our manufacturing stream, are designed and developed for military applications. This is good news for any company in need of aluminum investment casting parts or components that have non-military requirements, because we have learned to be extraordinarily meticulous about our quality control measures, many of which have triple redundancies.

The manufacturing tolerances to which we hold ourselves, and to which the military is totally unyielding, have made Nu-Cast a foundry that can be trusted to produce any aluminum casting product you need to the most exacting standards.

The military is known for being in the business of keeping America safe. We all completely understand and accept this most basic of truths. However, many of us do not take the thinking to the next logical level, which is that in order to keep America safe, the United States military must first do everything in its considerable power to keep our fighting men and women safe. At Nu-Cast, we take our responsibility in this process very seriously. We are entirely clear that every casting we make that holds night vision or infra red optics securely on a rifle barrel must be perfect because it may be the thing that saves a soldier’s life. We get it. Our dedication and commitment to maintaining strict adherence to our tolerances and standards define us. It is who we are.

All things being equal, wouldn’t you rather engage in a concurrent engineering process for your next aluminum investment casting needs with a company that lives and breathes perfection? Wouldn’t you rather bring your on-going casting needs to a casting company with a strong culture of quality control and to which our military entrusts the lives of our sons and daughters?

That company is Nu-Cast.